Bag type design

Pillow pack

Pillow pack string

Gusset/Block Bottom

Quad Seal Pack

Brick pack

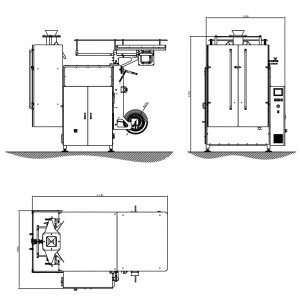

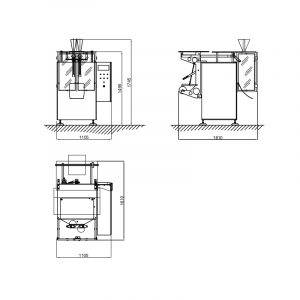

What are Vertical Packaging Machines?

Also known as vertical form, fill and seal (VFFS) machines, they create, fill and seal sachets and pouches.

These are fully automatic machines that can be paired with different dosing systems making them invaluable to all industries packing any product type.

An auger can be added for powder products, a weigher can be added for solid products and a liquid depositor can be added for liquids.

A reel of film is brought down into the machine and is sealed once to create a tube, then sealed again to form the bottom of a pack. Once the bottom is sealed, the product is dispensed into the bag which is then sealed before being cut and exiting the machine, likely via conveyor.

Accessories can be added to these machines such as labelling, coding and special closures.

Benefits of Our Vertical Packaging Machines

- Efficient – these machines can create up to 50 packs per minute.

- Compact – with forming, filling and sealing all in one unit they are ideal even for small facilities.

- Fully Automatic – with dispensing systems and exit conveyors this range of machine takes raw product and makes it shelf ready without the need for human interaction.

- Large Range – with various models there is a machine that will suit your production requirements and packaging sizes.

- Versatile – we can synchronise powder, liquid, granule and solids dosing systems with these machines meaning they can pack all product types.

- Customisable – additional features can be easily added e.g. coding, labelling etc.

- Adjustable – the same machine can pack different quantities of product into different sized bags. Format changes are easily done with just the click of a few buttons.