Descripción

Descripción

Las máquinas automáticas Postpack, S.L. de la serie MH-110, tanto en su versión simple como duplex, han estado desarrolladas para el envasado de productos en polvo, granulados, líquidos o pastosos así como para el envasado de toallitas refrescantes en sobres de tres o cuatro soldaduras.

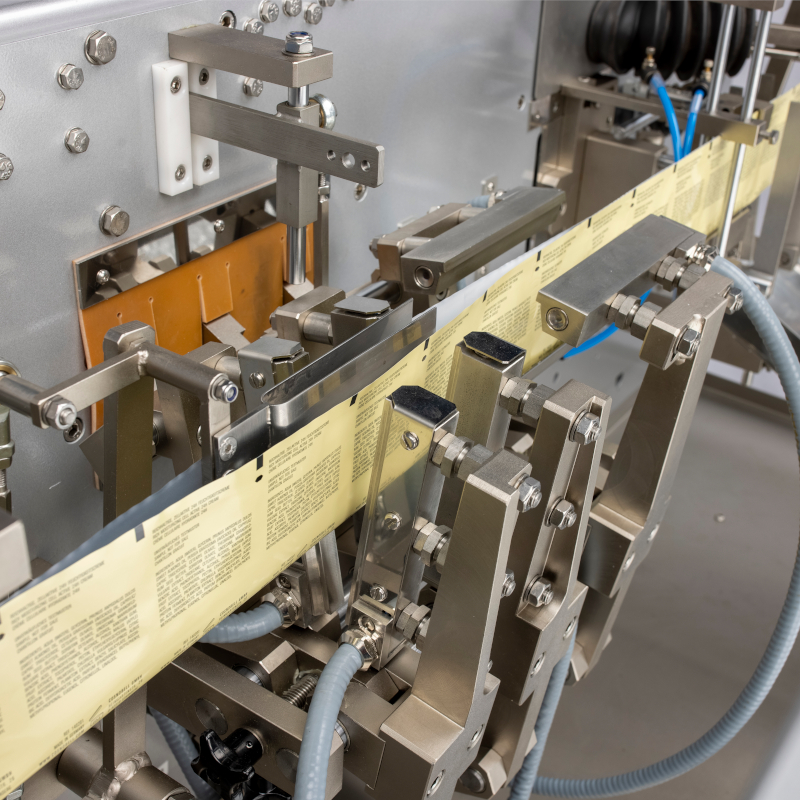

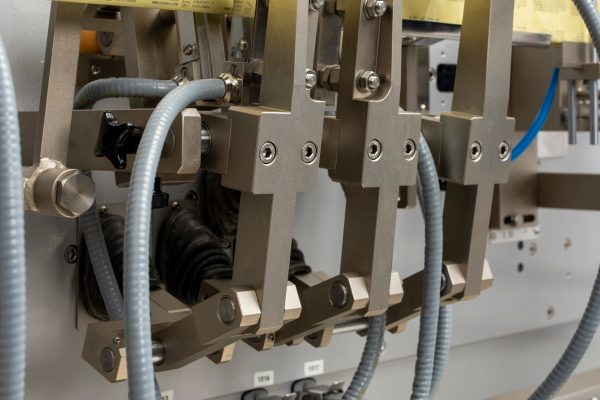

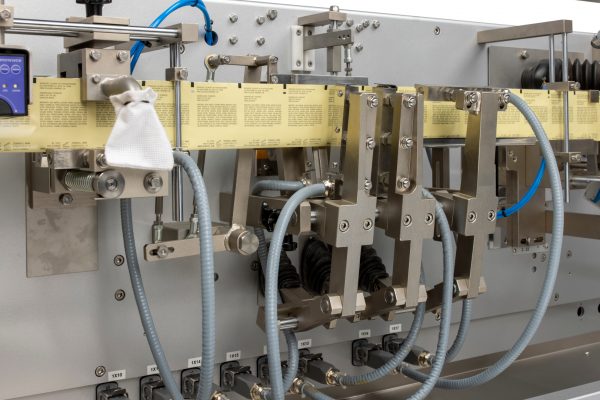

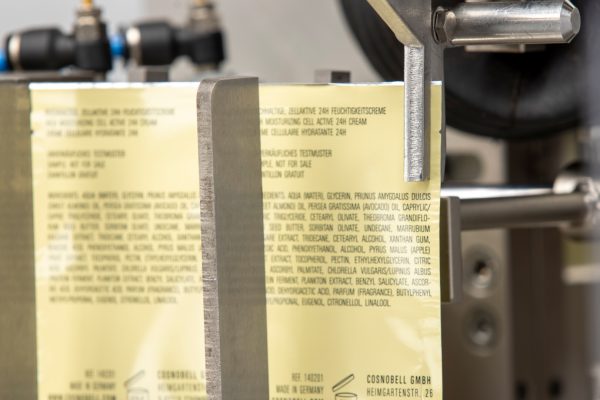

Partiendo de una bobina de material termosoldable, mediante plegado en forma de “V” y en ciclos intermitentes, confecciona por medio de mordazas de sellado, llena y cierra.

La dosificación puede realizarse en función del producto a envasar:

1.- Dosificador Sinfín para productos en polvo.

2.- Dosificador Volumétrico para granulados.

3.- Dosificador de líquidos o pastosos.

Datos técnicos + tipos y medidas de sobres

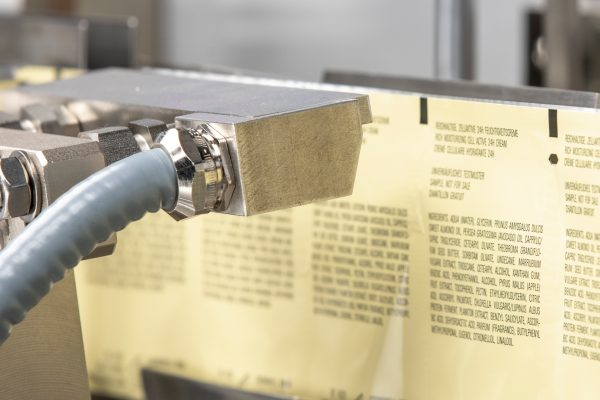

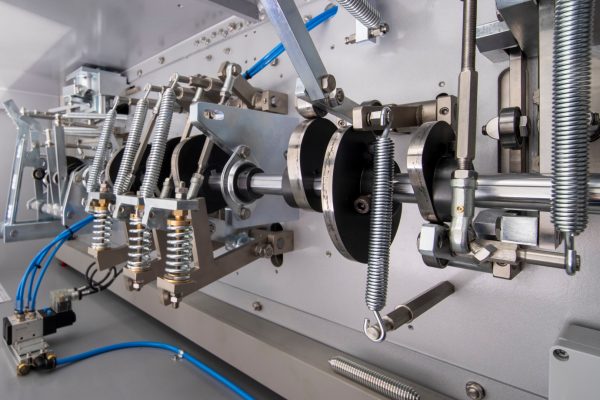

Galeria

Imágenes de la máquina en funcionamiento

Solicitar más información

Contactar

Si necesita más información puede contactar con nosotros mediante el siguiente formulario de contacto, y le responderemos a la mayor brevedad posible.

- Finalidad: Responder a su solicitud y enviarle información comercial de nuestros productos y servicios.

- Legitimación: Consentimiento de la persona interesada.

- Destinatarios: No se prevén cesiones de datos.

- Derechos: Puede retirar cesiones de datos. Puede retirar su consentimiento en cualquier momento y también acceder, rectificar, suprimir sus datos y otros derechos a través del mail postpack@postpacksl.com.

- Información Adicional: Puede ampliar la información en el enlace de Política de privacidad.